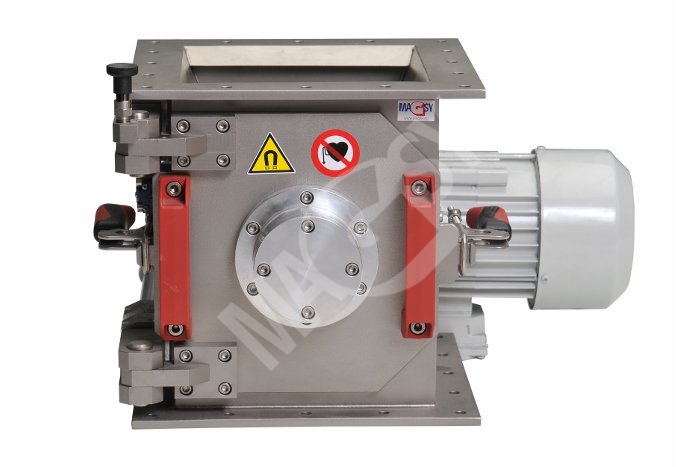

Telescopic rotational magnetic separator (MSVR)

Rotational magnetic separator consists of magnetic telescopic pipes located in the box structure ended by the flanges. Component with magnetic pipes is located on a shaft driven by the electromotor (400 V). Therefore, during the separation magnetic pipes are fluently rotating that is decreasing the risk of grinding through magnet covering pipes by an abrasive material, and also it is decreasing the risk of the separator clogging by a bulk material with not so good characteristics.

Rotational magnetic separator consists of magnetic telescopic pipes located in the box structure ended by the flanges. Component with magnetic pipes is located on a shaft driven by the electromotor (400 V). Therefore, during the separation magnetic pipes are fluently rotating that is decreasing the risk of grinding through magnet covering pipes by an abrasive material, and also it is decreasing the risk of the separator clogging by a bulk material with not so good characteristics.

The device is surface treated by sanding (for an extra cost it is also possible to supply in a polished version).

Magnetic separator is terminated by square flanges. However, we are able to meet your requirements regarding entering/outgoing dimensions and various ending types.

We are going towards each customer to maximum extent. Our products are made to measure your needs. CONTACT US

We are going towards each customer to maximum extent. Our products are made to measure your needs. CONTACT US

The product has been developed and is manufactured by our company. Both servicing and assembling activities are performed by our trained technical experts.

The product has been developed and is manufactured by our company. Both servicing and assembling activities are performed by our trained technical experts.

MORE INFORMATION ON A SPECIALIZED WEBSITE

Separator benefits

- Very high separation efficiency.

- The device is made of the stainless steel of the class 1.4301.

- Rotating pipes are driven by an electromotor.

- There is decreased risk of pipe grinding through using an abrasive material.

- There is a possibility of the magnetic pipe rotation speed.

What materials can be sorted

- Bulk materials and materials with a worsened permeability

- Materials tending to the bridging

- Abrasive materials

Rotation separator construction

Magnets are inserted into a stainless-steel casing so they are protected against damaging; their cleaning is very simple, fast and comfortable. Magnetic pipes are located on the rotational shaft driven by the electromotor. It is possible to change rotational speed of magnetic pipes based on the type and quality of separated material.

Rotating magnetic pipes

Magnetic separator is equipped with very strong rare-earth magnets (NdFeB) with the magnetic induction of 10.400 G (by request we can also use magnets with the magnetic induction of more than 14.000 G!). The diameter of the magnetic telescopic pipe is 30 mm, pipe wall thickness is approximately 0.7 mm. The device is made of the stainless steel of the class 1.4301 exclusively.

Magnetic separator cleaning

Removal of caught metal impurities is very easy. After releasing the clips, pull the magnetic pipes out of the separator body. Then tilt the door out and fix it in this position by the safety peg. Put the collecting vessel onto the magnetic pipes. As the last step, take the pipes together with the collecting vessel out of the magnetic cores. Caught metal particles fall out to the collecting vessel and the magnetic separator becomes cleaned.