Magnetic rollers are used to separate metallic components and particles from bulk mixtures (wood, aggregates, coal, nonferrous metals, waste mixtures). Self-cleaning magnetic roller is incorporated as a return roll of a belt conveyor on which material is transported for separation. Metallic particles are trapped with the magnetic roller and taken away as far as behind the roller axis where their separation takes place and metals fall off spontaneously - please see the animation.

Magnetic rollers are used to separate metallic components and particles from bulk mixtures (wood, aggregates, coal, nonferrous metals, waste mixtures). Self-cleaning magnetic roller is incorporated as a return roll of a belt conveyor on which material is transported for separation. Metallic particles are trapped with the magnetic roller and taken away as far as behind the roller axis where their separation takes place and metals fall off spontaneously - please see the animation.

Use of the magnetic roller will improve quality of processed material considerably. It is also suitable to utilize it wherever it is necessary to protect downstream equipment against damage caused by metallic particles. In case of a thicker layer of transported material, we recommend its using also in a combination with a magnet above the conveyor that will allow separating metals from the top layer of separated material effectively.

Use of the magnetic roller will improve quality of processed material considerably. It is also suitable to utilize it wherever it is necessary to protect downstream equipment against damage caused by metallic particles. In case of a thicker layer of transported material, we recommend its using also in a combination with a magnet above the conveyor that will allow separating metals from the top layer of separated material effectively.

We are going towards each customer to maximum extent. Our products are made to measure your needs. CONTACT US

We are going towards each customer to maximum extent. Our products are made to measure your needs. CONTACT US

The product has been developed and is manufactured by our company. Both servicing and assembling activities are performed by our trained technical experts.

The product has been developed and is manufactured by our company. Both servicing and assembling activities are performed by our trained technical experts.

MORE INFORMATION ON A SPECIALIZED WEBSITE

Animation of the magnetic roller functioning

Magnetic rollers are fitted with ferrite magnets. They can be fitted with very powerful rare-earth magnets. We can adapt the dimensions of the magnetic roller to the demands of the customer. It will find its application at waste recycling (to obtain magnetic materials from waste mixtures), in sawmills quarries, mines.

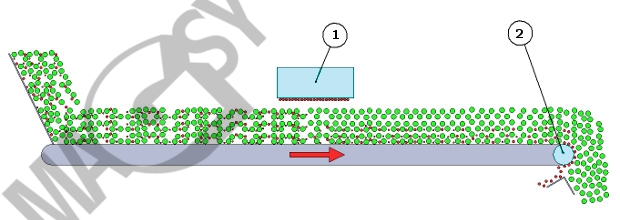

A useful tip for you – even more efficient metal separation on a conveyor belt

In order to achieve a maximum separation efficiency, during metal separation from a higher material layer on a conveyor belt, we recommend to use – except a magnetic plate or a separator situated above a conveyor (1) – also magnetic roller (2). The device is capable of separating metals from the lower layer part.